The Philippines

1996

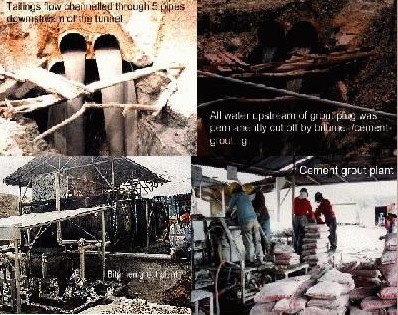

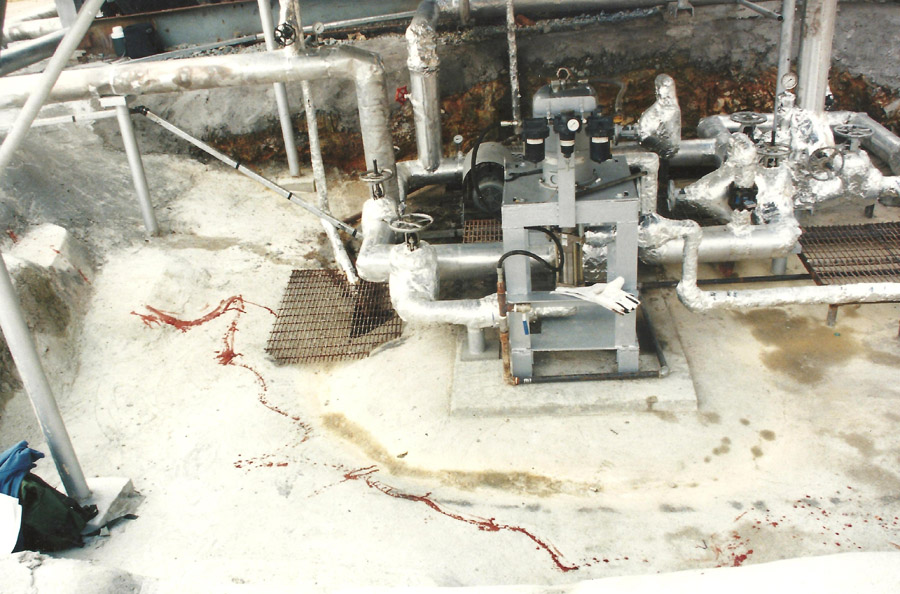

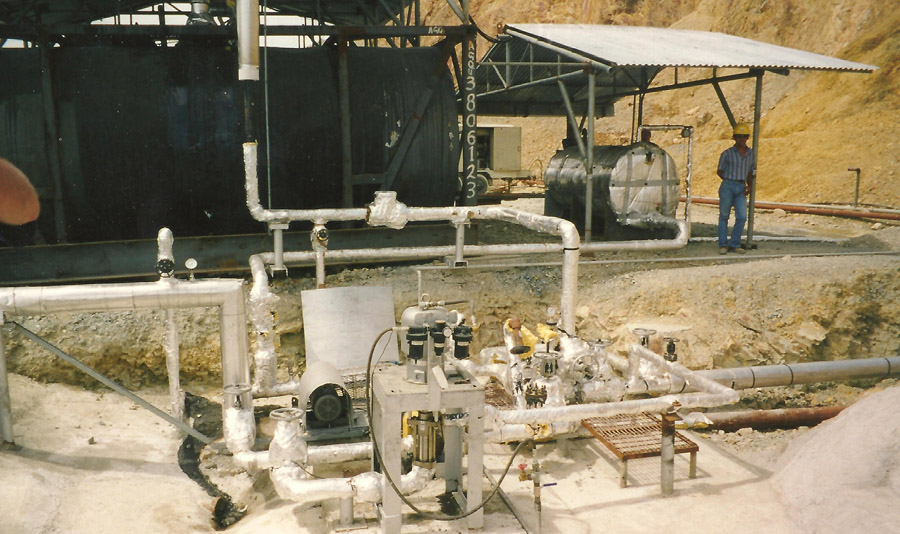

Hot bitumen injection, in conjunction with regular cement based suspension grouts, was employed to stop a major tailings flow, which peaked at approximately 7,000 l/sec (111,000 usgpm). The flow came from an old access tunnel connecting a very large mined out open pit, filled with tailings slurry. The tunnel was initially sealed with a concrete plug that blew after an earthquake, allowing the slurry to flow through the tunnel, into the river, and on into the ocean, causing a major environmental disaster in 1996. The tunnel was located 170 metres below ground, running under a mountain. Drilling was done from surface and a “bitumen-cement grout plug” was formed under these adverse conditions. At the time, it was the deepest hot bitumen grouting program ever conducted. The more than 100 m long plug was subsequently drilled, re-grouted and reinforced, transforming the plug into a permanent structure.