Australia

Pilot holes were drilled from the surface to the mining horizon, approximately 1000 meters below surface. Inflows as high as 100 liters per second were encountered at depths of 300 to 400 meters below surface.

The zone in which the inflows occurred was very erodible and the fissures were not amenable to regular cement based grouts. The inflows through the two pilot holes extended into the workings of the mine causing operational delays. ECO determined that the holes had to be reamed out to a diameter several times the size of the original pilot hole. As the conditions of the mine were rapidly deteriorating, it was necessary to perform a grouting program with a fast setting grout, which was amenable to the formation and provided the requisite grout spread to enlarge the pilot holes.

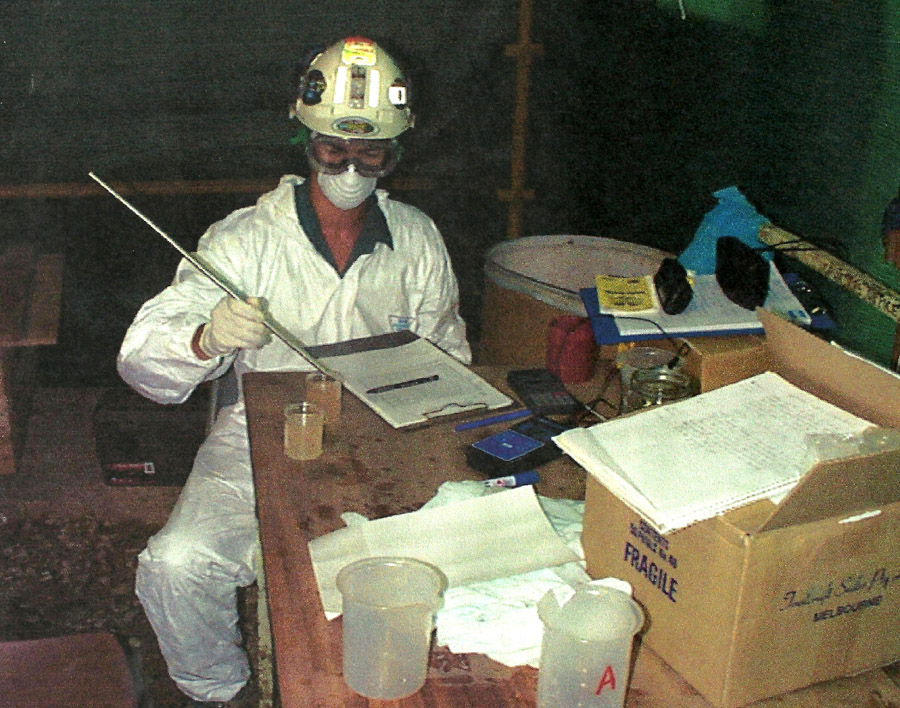

ECO designed an acrylate grouting program in which a tough elastic Na-Mg acrylate (Akogel Rubbery) was used. A set time of 20 minutes was selected to facilitate timely movement of the packer. Several grout passes with this acrylate grout were needed to create an effective grout curtain around the pilot holes.

ECO provided the lab-testing to develop the mix design, performed the on-site engineering and directed the grouting operations.