Taiwan

January - May 2002

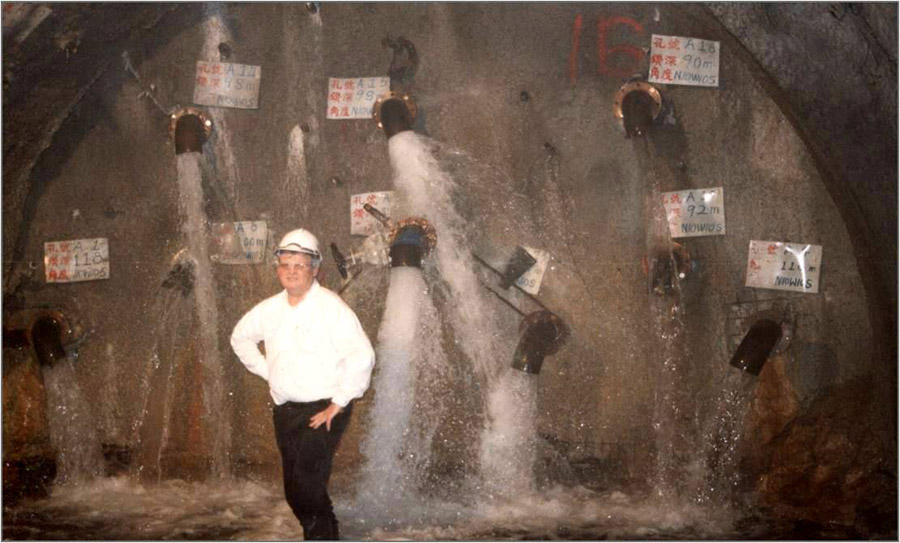

The hot bitumen grouting program at the New Yung Chung Tunnel was undertaken for the Taiwan East Railway Improvement Engineering Bureau by JINES Construction with project design and on-site direction provided by ECO. The program was designed to enhance the stability of the rock mass (a badly fractured water bearing formation under up to 50 bar (750 psi) hydrostatic pressure) surrounding the planned tunnel excavation and decrease the permeability of water bearing marble zone (which could produce up to 84 cu. metres/minute inflow) and adjacent highly sheared greenschist in advance of excavation of two tunnels (10 m and 7 m diameters).

There were several important technical challenges that had to be overcome in order to successfully inject the formation:

grouting in the presence of severe flow conditions;

high formation water pressures and the presence of fine fissures only, resulting in the need for injecting hot bitumen at very high temperatures;

ensuring an adequate supply of the appropriate types of bitumen during grouting was available

health and safety issues working within a tunnel; and,

no ‘off the shelf’ grout pumps were available that could handle the combination of high pressure and high temperatures and a custom designed grout plant had to be built on short notice.

The hot bitumen grouting program conducted in the New Yung Chung Tunnel resulted in a reduction in the hydraulic conductivity of the formation surrounding the main tunnel of approximately 95 %. This is likely the first bitumen grouting program ever conducted entirely from within a tunnel.