Malaysia

1992

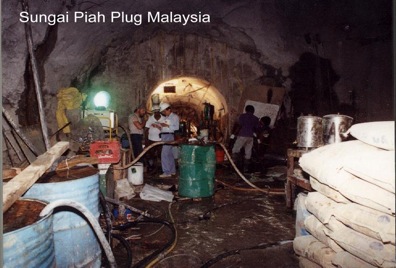

For the Sungai Piah Hydro Electric Project, ECO assisted SNC Lavalin with the design and the site engineering of the sealing techniques around a massive concrete plug subjected to 5 MPa (715 psi) water pressure. The length of the plug was 27.35 metres total, (massive hollow plug), with massive concrete “end zone” of 7 metres.

The tunnel in which the plug was installed was approximately 9m high and 11m wide in largest (widest) sections. A grouting program was implemented after the plug had cooled off. It was performed under flow conditions (20 litres/second) through faults.

Backfill grouting was performed using cement based grout in conjunction with polyurethane grout (to eliminate washout). Injection of the cold joints between 8 concrete sections was done via injectable tubes strategically placed in all the cold joints and at the rock/concrete contact zone. Contact grouting was carried out using water reactive, hydrophobic, flexible polyurethane with a 2-component polyurethane elastomer. The grouting of the formation around the plug was carried out with cement based suspension grout in conjunction with water reactive polyurethane grout. Formation grouting via secondary and tertiary holes was subsequently carried out with cement based suspension grout and higher order holes were injected with polyurethane grout.